Ideas into Reality: Biomedical Make-A-Thon is Education in Action for Engineering Students

Onion slicers, Pez dispensers and weekly pill planners: Over a 48-hour period, engineering students found inspiration from these ordinary objects as they gained practical design experience at the 11th annual Medical Make-a-Thon, held Jan. 17-Jan.19 in the College of Engineering at the University of California, Davis.

The annual event is hosted by the Biomedical Engineering Society, or BMES, in coordination with the TEAM Lab and takes place throughout the lecture halls and hallways and across workbench tables in the Genome and Biological Sciences Facility.

BMES and TEAM Lab put the event on as an opportunity for undergraduates to apply their engineering skills and receive hands-on experience in product design and prototyping. They intend it as preparation for the students’ capstone design projects and as a launching pad for potential careers in the biomedical industry.

New Year, New Solutions

Like a hack-a-thon, the competition tasks student teams to create solutions to a problem within a set timeframe. The spin is the issues are unmet medical needs identified by BMES after conducting interviews with UC Davis professors and doctors, with each year having a new challenge to solve.

This year’s charge was to create a device that accurately splits pills for people with physical and visual disabilities — specifically, neuropathy and retinopathy caused by diabetes. More than a quarter of all individuals with diabetes experience one or both diseases, which impair vision and other sensory abilities.

“Because of retinopathy and neuropathy, splitting pills is difficult and can lead to ramifications such as inaccurate dosing, reduced compliance and overall inability to split pills without assistance,” said Asia-Denay Blue, a biomedical engineering senior and BMES student organizer for the event. “Addressing these needs requires innovative solutions to overcome the limitations of existing tools on the market.”

While pill-splitting tools currently available are useful, they are burdensome for patients with visual and sensory impairments. This is because the tools require users to position the pills in specific spots while also having accurate aim and dexterity when applying pressure with the blade.

Ready, Set, Design

On the evening of Jan. 17, the 48-hour timer began ticking down for the 15 participating teams to develop a pill-splitting device that users can operate without the need for precision, strength or vision.

“This prompt is well-suited to the constraints of our event,” said Steven Lucero, the TEAM Lab director and a mentor for students throughout the make-a-thon.“It presents a reasonably challenging problem, features clearly defined and quantifiable objectives and is physically compact enough to allow for manufacturing within our condensed timeline.”

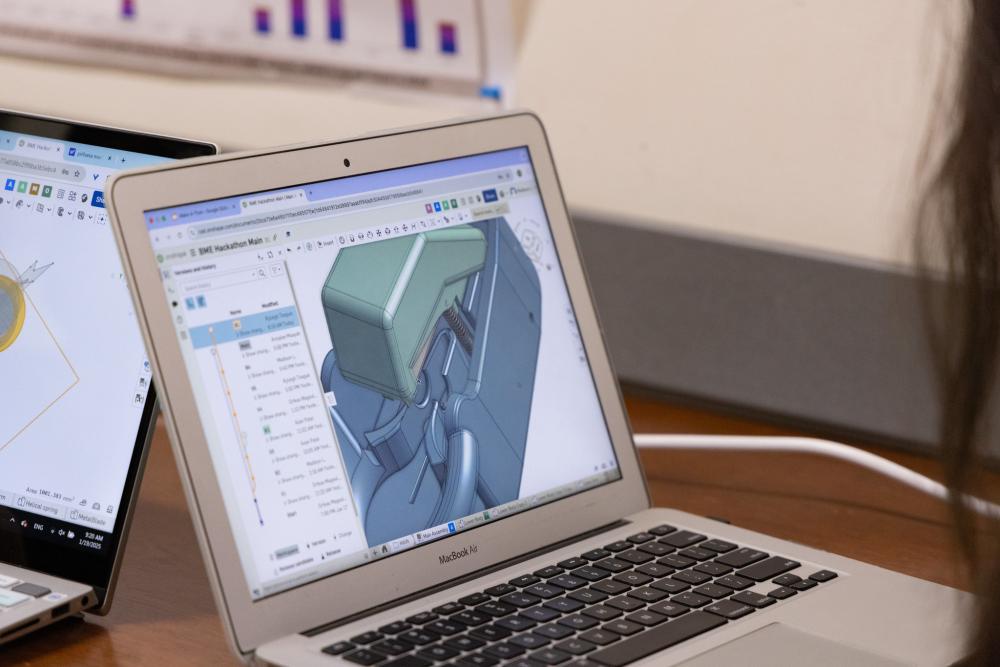

Each team had just hours to create an initial 3D model of their product using Computer-Aided Design, or CAD, software, such as Autodesk Inventor and SOLIDWORKS Student Edition. This is where students turned to Pez dispensers and onion slicers to help kickstart their own ideas.

By noon the following day, the teams had to submit their CAD design for a new pill-splitting device and prepare a 5-minute pitch to sell their product to a panel of judges. The judges included UC Davis staff and faculty, like Lucero and lecturer Donald Chigazola, and industry experts with ties to the Department of Biomedical Engineering, like alum Allie Brunson who now works as a test engineer for 2G Engineering, a Winsconsin-based company creating subsea electrical and mechanical solutions.

From these initial design presentations, the judges selected the three teams with the most robust designs to advance to the next round of competition: prototyping. The other 12 continued to refine their ideas. There were still several design awards up for grabs, after all.

So Prototypical

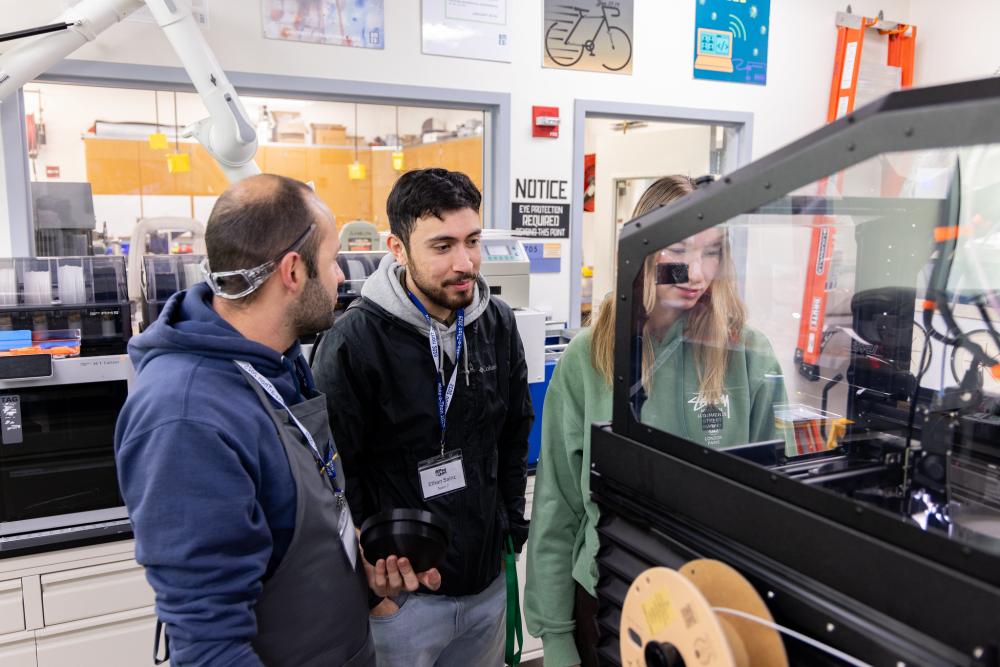

By the afternoon of Jan. 18, the prototyping teams moved into the TEAM Lab to transform their CAD files into prototypes.

“Teams participating in our prototyping round quickly recognize the distinction between proposing a conceptual solution in a CAD environment and creating a functional, real-life design,” Lucero said.

Working through these translational challenges, the students used different manufacturing processes, like 3D printing and laser cutting, as they continued late into the night to create a working prototype with help from mentors like Lucero and Valerie Quiroz, another TEAM Lab development engineer.

Their final prototypes had to be packaged and ready for a second round of presentations by 11 a.m. on Jan. 19. In addition to doubling the presentation time to 10 minutes, the judges also put the prototypes through a series of tests to see how easy the devices were to use and their effectiveness for cutting different pill shapes, for example.

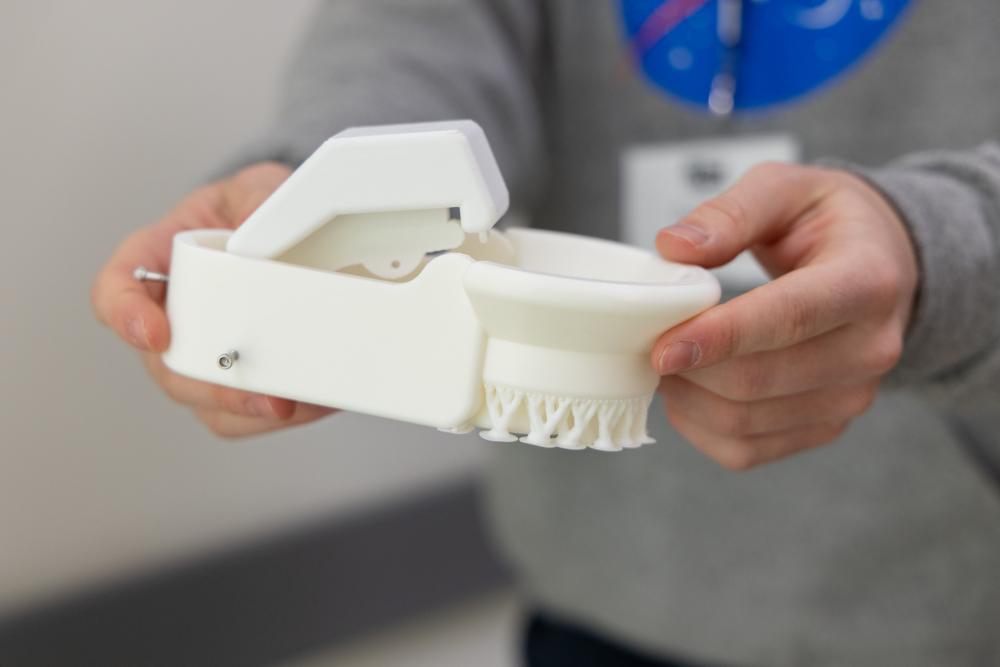

The students who took home the prize for the best overall prototype were the designers of ExactaPill — a design with a stapler-like appendage for users to press down on to cut their pills easily. A basin attached to the arm catches the split medication.

“This has been an incredible experience,” said Orfeas Magoulas, a mechanical and aerospace engineering student and member of the ExactaPill team. “Not only have we been able to participate in the design process, we’ve been able to go that next step and turn this [product] idea into reality.”

In total, the judges recognized five teams, with awards ranging from the most creative design to the team with the product idea that had the highest potential.

“Ultimately, every team arrives at a device that makes meaningful progress toward the prompt and finds the experience both rewarding and educational,” Lucero said.